Kay archtop neck reset / bridge install (update)

I’m a high school art teacher in Memphis, starting to dabble in instrument building trying to develop a future art class

for my students.

Trying to learn / figure some stuff out. I picked up an old Kay, hard to date it, possibly 1930’s? it had a loose neck and no truss rod or steel reinforcement.

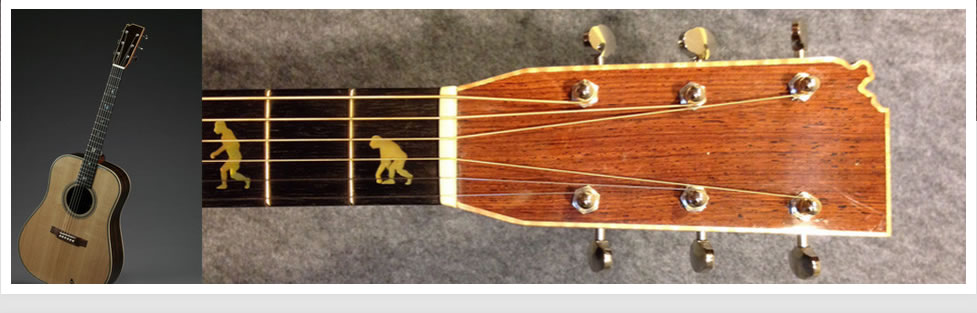

I steamed the neck off, pulled the fret board, installed a hot rod, replaced my inlays.

How do I reset my neck on an archtop with no bridge? If I put the dove tail back in place, and line up my new bone saddle bridge, my straight edge hits about ½ inch from the top of the saddle, too high? I’ve read it should be 1/8th?

Do you just really set the neck back on an archtop?

Forgive me if I’m new or asking dumb questions. Your website has been the closest answer I’ve found.

Thanks for any advice

Grant

Fine Arts Instructor

Memphis University School

Grant,

I would start by fitting the new bridge. It is sad that the original bridge is gone. It was Brazilian rosewood. Figure out where the bridge should go. Measure from the High E nut slot to the 12th fret. Double it and add 1mm. Measure from the low E nut slot to the 12th fret. Double it and add 3 mm. Get some sticky backed 150 or 180 grit sand paper. Mark a line across the sandpaper defining the above measurements. If the finish is old and flaky stick the sand paper to your shirt a few times to dull the stickiness. It is possible to hand hold the bridge and rub it back and forth over the sand paper until the feet fit, but it is very hard not to round the feet slightly. You can scrape the feet flat, or get a handy tool from Stewart-McDonald that uses the adjustment screws to bolt on a jig with a stabilizing wheel to keep the feet flat. Note that the sand paper must be wide enough that the wheel can run on it to keep everything level.

Now that you know exactly where and how high the bridge is (set the adjustment wheels in the middle so that you have some room to move), Aim the neck at it. The 1/8" thing is the height of a bone saddle above the top of a flattop bridge. With the neck straight, a straight edge laying flat along the top of the frets should point to a spot about 1/8" below the top of your new arch-top bridge.

Wood changes shape every time the weather changes. If the neck warps forward the string tension won't let it return to its original shape. So you may need to take a little wood off where the cheeks of the heel touch the sides. But, the dominant factor with Kays is that their dove tails were never properly fit. They were cut too loose and then floated together with hide glue. As the glue broke down, a gap would open at the bottom of the heel. Closing that gap by shimming and shaving the dovetail will be the largest factor in aiming the neck at the new bridge. Remember to keep the neck centered as you cut it back.

I answered a question a few days ago that was tangent to your question. I have inserted it here:

Steve,

I was recently doing some research online trying to find out the difference between a "Steel Reinforced Neck" (found on a lot of old Harmony and Kay model guitars), and an actual truss rod. Is a steel reinforced neck just a neck with a truss rod that is not adjustable, or is it something different? I like the vibe of some of the old Harmony archtop models like the "Broadway" and "Monterey", and i have been considering purchasing one. I am a little skeptical of buying anything without a truss rod, and I don't know exactly what the "Steel Reinforced Neck" is. Any insight you can offer would be greatly appreciated. Thanks for your help.

Sincerely,

Brett

Brett,

"Steel Reinforced Neck" was industry code for, not adjustable, used by cheap guitars in past times. I can't remember the last time I saw "Steel Reinforced Neck" on a new guitar. It means there is a steel reinforcing bar in the neck. There is nothing under the fake truss rod cover that says, "steel reinforced neck". Essentially all guitar necks are reinforced with something: an ebony, steel or carbon fiber bar, or one of various styles of adjustable truss rod. If the truss rod cover does not say "steel reinforced neck" there is an adjustable truss rod, but it is probably broken. Kays and Harmonys had "over under" rods. The adjustment nut would shorten the bottom rod, arching the top rod and bending the neck backward. This is a fine concept, and the basis for many modern truss rods, but at the non-adjusting end, the two rods were held together with a shaky spot weld. It was very common for the spot weld to break, leaving the rod useless.

To straighten a Steel Reinforced neck we pull the frets, plane it to the proper drop-back so that the string tension will pull it perfectly straight. Then we install, level, round and polish new frets and you are good to go. Normally, when a truss rod breaks, the neck warps forward. It is sometimes possible to plane and refret the neck and have it play great, with a broken rod. A new rod is the best way to go. As you shop, realize that most of the truss rods you deal with are broken or will break with your first attempt to adjust them.

Another important thing to look at is the joint between the neck and the body. Truss rods only work from the first to the 14th frets, they basically move the 7th fret up and down. If the warp you see is at the 14th fret, your problem is the neck set. It is possible to set routers to cut a dovetail that fits perfectly, but, in production, the cutters get dull after many cuts, and also, the wood changes shape after it's been cut. In practicality, the only options are: cut the dovetail too tight and hand shave it until it fits perfectly, or cut it too loose and float it together with glue. Martin and Gibson used the former method, Kay and Harmony, the latter. The hide glue that they used broke down and a gap appeared at the bottom of the heel, allowing the neck to pull forward and requiring the bridge to be impossibly low. Resetting a Kay or Harmony neck is quick and easy. Just pop it off, shim and shave it tight and reglue it with hide. Unfortunately, most of these guitars have had their necks reset by home hobbyists with a unclear concept of the problem. It is very common to see various horrors: the gap filled instead of closed, the joint refloated with epoxy, nails, screws etc. Resetting an epoxied neck can be dauntingly expensive.

Those old, American made, pressed top, arch top guitars were of no interest to anyone until the last few years. Now everyone is looking for one. We have restored quite a few. A full meal deal, including a new truss rod, plane and refret, neck reset and regluing cracks and open joints can run six to eight hundred dollars. Never refinish one. The funky is part of the appeal. Happy hunting.

Steve Mason

Return to Questions

|